Fire protection systems for modular and edge data centers typically use spot smoke detectors to identify possible threats as quickly as possible. Aspirating smoke detectors (ASD) may be used for very early smoke detection in the incipient stage of a fire. Gas detectors may be used where batteries (i.e. lithium-ion) are deployed. Even with the best of these fire safety detectors, the precise location & source of the potential threat is difficult to pinpoint, especially in high airflow environments, where smoke and gasses can be quickly transported away from the source.

What are the principal fire threats in most modular & edge data centers?

- Electrical feeds including PDUs, transformers, & inverters — short-circuits, electric overloads, power & grounding faults

- Batteries & UPS — overheating & thermal runaway

- Mechanical systems — AC & ventilation system anomalies & failure

- Leaks — water, battery electrolytes, fuels

In most cases, abnormal equipment heating precedes the presence of smoke or gas. To detect this overheating, early warning thermal imaging sensors, like those from ServersCheck, can monitor and detect a variety of threat conditions that, if left unchecked, could lead to a fire. These sensors do not replace fire safety systems — they complement them well by pinpointing the source, providing additional time to investigate a potential threat before it can escalate.

Traditional temperature sensors measure the air temperature near the target equipment, limiting their effectiveness for detecting overheating. Thermal imaging sensors record 2-dimensional images of surface temperatures on the target equipment. This is important for precisely locating the source of the overheating.

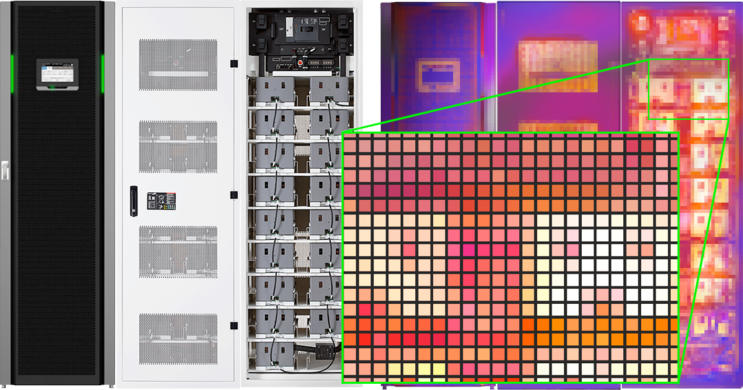

Since thermal imaging sensors detect light in the infrared range (IR), they need no visible light for analysis and are ideal in dark enclosures. The thermal images produced by the sensors provide an image with colors ranging from black to blue, red, and yellow indicating increasing temperatures. Abnormal hot spots on the equipment can easily be identifies, as well at the intensity.

Portable (i.e. hand-held) thermal imaging equipment has been used for years for installation surveys and periodic inspections of electrical switchgear, IT equipment, PDU, and UPS modules. Indeed, these inspections may be required before a data center becomes operational. However, data centers need to be available 24/7/365, so continual monitoring with thermal imaging sensors is more appropriate for fire safety.

Besides fire prevention, thermal image sensors can also improve equipment uptime and prevent failure with early warning of potential overheating. Additionally, thermal imaging can assist with cooling and ventilation tuning to direct airflow to potential hotspots in the data center enclosure.

As an example, ServersCheck thermal imaging sensors will monitor up to 19,200 individual points every 2 seconds with varying fields of view (FoV) and temperature accuracy. A variety of equipment ranging from electrical panels, to switch gear, PDUs, UPSs, and even server racks can be monitored to provide very early detection of potential fire threats.

The sensors are networked and powered by PoE with temperature data delivered continually to a building management system (BMS) or industrial and IT automation platforms via Modbus TCP, RTU (RS485), or SNMP.

In the accompanying image, a PDU is being monitored by a thermal imaging sensor sensor at < 20 feet. Hot spots can be identified, and temperature changes or thresholds can alert management systems of a potential problem depending on the specified operational temperature range.